Insulation Ceramic Fibre

INSULATION – Ceramic fibre 1260˚C and 1400˚C

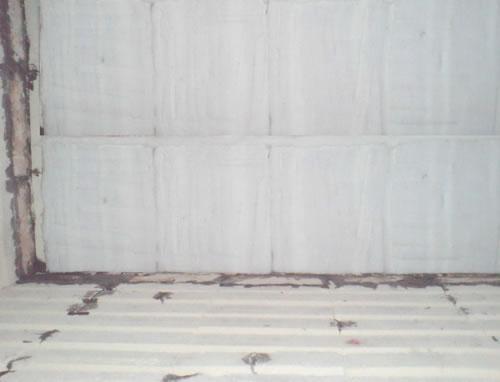

Module Roof Insulation

Modules are typically 300x300mm and produced with any desired thickness to provide best insulation.

Module density is optimised to minimise energy loss through furnace lining. The lining density can, to a certain extent, be manipulated to obtain optimum insulation and minimum heat loss.

Modules can be manufactured to benchmark temperature (1260˚C) or high temperature (1400˚C) standards.

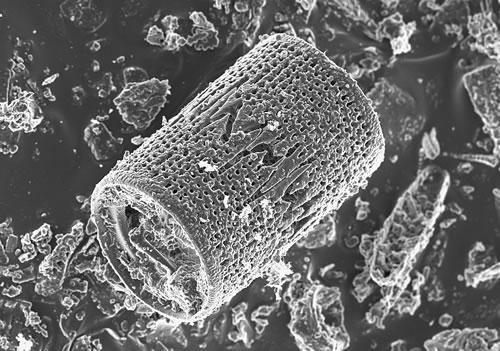

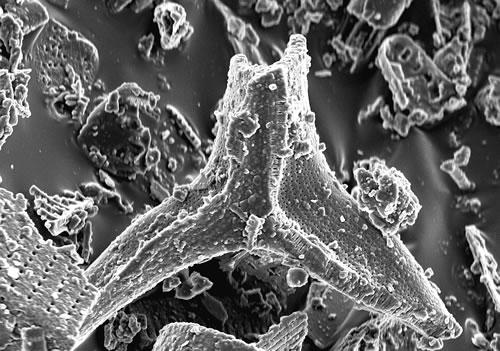

INSULATION - Kiesselguhr (Diatomaceous earth)

Refractory metallurgical covering.

For molten steels, irons in steelplants (ladles, tundishes) and foundries (ladles, sleeve insulated feeding systems and runners).

A measured addition with a thickness of merely 2-3cm will stop radiant and convective heat loss from the top of furnaces, ladles or risers.

Kiesselguhr is also used as an insulating ingredient in vacuum formed sleeves for molten metal feeder systems in foundries.